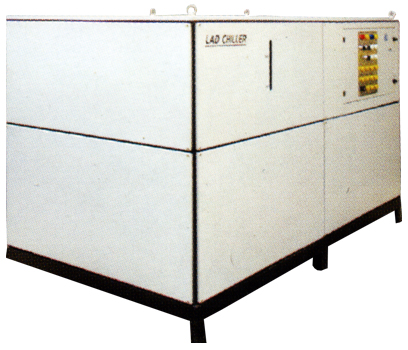

We manufacture completely redundant chiller for SWAS systems in power plant. We offer all variant in small and large capacities

In typical thermal power plant environment, water & steam are in constant contact with metal surfaces & corrosion is unavoidable. To to maintain the integrity of plant equipments, the purity of working fluid "water" & steam is crucial.

ANUCOOL offers cost-effective chillers, for on-line Steam & Water Analysis Systems (SWAS), which form integral part of today's plant automation methodologies. A chiller provides cooling, bringing samples from different circuits down to a specified temperature, where they can be analyzed. These are available in cooling capacities of 1 to 15 TR.

Similarly, for Continuous Emission Monitoring Systems (GEMS), ANUCOOL offers Gas Coolers, for bringing down the temperature of the flue gas samples taken from the stack, down to a specified temperature and humidity, where they can be analyxed. These are available in 1, 2, 3, 4 gas paths, 50 & 60 Hz models.

In any power plant running on steam, the purity of boiler feed water and steam is absolutely crucial; especially to steam equipments like Steam boiler, Steam turbine, Super heater, Condenser etc.

Steam and Water Analysis Systems (SWAS) provide exact, precise measurements on all these critical parameters, to keep the power plant continuously running, with minimum erosion and corrosion. These are equipped with modern on-line analyzers such as Silica, Sodium, Dissolved Oxygen, pH & Conductivity etc.

SWAS analyzers work more efficiently and effectively if supported with a well engineered sample cooling method. As per the standard, the analysis should be carried out at sample temperature of 25+/- 1 Deg. Centigrade.

ANUCOOL provides cost effective Chiller systems for these SWAS applications. A typical chiller system is comprised of a tank or container, generally known as Isothermal Bath in which the sample coils are immersed. The refrigerated chiller unit continuously supplies chilled water to Isothermal Bath and thus temperatures of samples are cooled down to desired values and sent further to analyzer.