New Anucool Engineers manufactures a wide range of Printing Chillers. The company has been successful in fulfilling stringet requirements of quality, performance and reliability in printing industry. it has established itself as a regular supplier of chilled as well as non-chilling fountain solution circulation systems to a number of prestigious print Houses in India & abroad.

Printing Chiller, also known as Fountain Solution Chillers, is specifically designed for today’s most sophisticated, Multi Tower Web Off-set Printing presses.

Printing chiller continuously supplies Water based chilled water fountain solution, to be passed over the print rollers. This leads to reduction of stretching and bleeding. This in turn decreases the time needed to print which improves efficiency and leads to higher quality final print at a cost savings.

Printing Chiller Installation Layout PDF

RWCT - Best in class printing chillers for your modern web offset printing press of 1,2,3,4 up to several tower system. We have our installations in almost all newspaper press in India.

CHILLMATE model is fully equipped with PH and conductivity meter, sensor and mechanical doser of dosatron make.

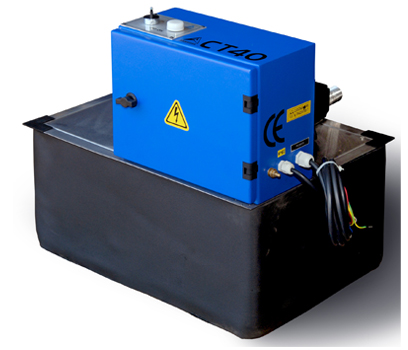

Collection tank We have 40 ltr and 90ltr model of return tanks.

PH and Conductivity meter- It displays the value of PH and Conductivity in fountain solution

PH and Conductivity meter- It displays the value of PH and Conductivity in fountain solution

Salient Features

- Optimum Reliability

- Adequate Redundancy

- Status Indication

- Long Life

- Temperature Control

- Filtration

- Circulation

- Auto Doser

- pH & Conductivity meter

- Stand - by arrangement for overflow protection

- Separate electrical panel

- Microprocessor based programmable Controller

- Computer Connectivity

- To maintain steady flow rate of Fountain Solution to Print Units

- To maintain appropriate concentration of Fountain Solution in water using auto dosing unit

- To carry out multiple filtration of Fountain Solution

The used solution from print units is first collected in separate tank by gravity, from where it is continuously pumped to main Printing Chiller tank. The solution is filtered and the refrigeration system removes the heat from the solution using immersed stainless steel coils and thus chilled solution is again fed to print rollers. And the cycle repeats.

Main Features

- Plug & play type self contained units with small footprints

- Use of Stainless Steel tanks and coils for corrosion-free and durable operation

- Magnetically coupled process pumps for 100% leak free working

- Adsorption based Multiple filtration arrangement

- Adequate Safety Controls for human and machine

- Visual management of Fault indication by flashersn

- Main chiller tanks offered are 50,80,100,200,400 Litres with common 40 Litres Collection Tank

- Approved by prominent OEMs and publishing houses in India

- CE certified

Optional Accessories

- PH and Conductivity Meter from Thermo Fisher, USA

- Auto Dosing unit from "DOSATRON" France

- Process pumps from "Brinkman" Germany / "Grundfoss" Denmark

- Redundancy for Pump; Water Level Controlling is offered on demand

- Computer connectivity through USB